Inode Technologies offers a powerful Production Floor Monitoring System designed to give manufacturers real-time visibility and control over their shop floor operations. Our solution helps production managers track machine performance, analyze downtime, and improve overall equipment effectiveness (OEE)—all from a single, easy-to-use platform.

A Production Floor Monitoring System (PFMS) enables real – time monitoring of machines and production lines, providing instant visibility into operations. It captures key metrics such as cycle times , throughput, and downtime , helping to identify bottlenecks . The system integrates with IOT devices to automate data collection and trigger alerts for issues like equipment failures. With detailed dashboards , users can easily track performance , quality , and energy consumption. It lso offers production scheduling to optimize workflow and resource allocation, PFMS supports defect tracking , ensuring high product quality. The system promotes preventive maintenance by sending alerts based on usage. It includes workforce monitoring to track operator efficiency . Finally , it integrates with ERP systems for streamlined data flow across the organisation.

Key Features of Our Production Floor Monitoring System

-

Real-Time Machine & Process Monitoring: Instantly view the status of every machine and production line.

-

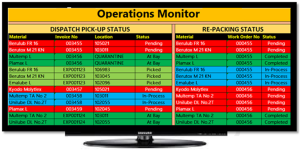

Live Dashboards & Analytics: Visualize production data with customizable charts and key performance indicators (KPIs).

-

Downtime & Alert Management: Receive instant alerts for machine stoppages or production delays.

-

Work Order Tracking: Monitor progress of each work order from initiation to completion.

-

Quality Control Integration: Track quality metrics and record inspection data directly on the system.

-

Role-Based Access Control: Secure, permission-based access for operators, supervisors, and managers.

-

Seamless ERP/MES Integration: Connect easily with existing ERP or Manufacturing Execution Systems.

Benefits for Your Manufacturing Operations

-

Increase Productivity: Identify bottlenecks and reduce downtime with real-time insights.

-

Enhance Decision-Making: Data-driven dashboards enable faster, more accurate decisions.

-

Improve Quality & Compliance: Monitor quality checkpoints and maintain production standards.

-

Optimize Resources: Better planning of manpower, machines, and materials.

Why Choose Inode Technologies

With deep expertise in manufacturing automation and custom software development, Inode Technologies creates tailor-made production monitoring systems suited to diverse industries—automotive, engineering, electronics, agriculture, and more. Our team provides end-to-end support from requirement analysis and UI/UX design to deployment and maintenance.

Drive Smart Manufacturing with Inode Technologies

Transform your shop floor into a smart, data-driven production environment. Partner with Inode Technologies to implement a Production Floor Monitoring System that improves efficiency, reduces costs, and delivers measurable business value.

WhatsApp us

WhatsApp us